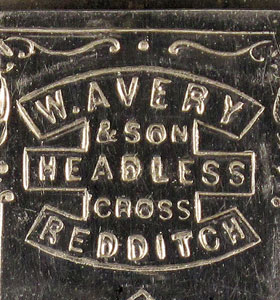

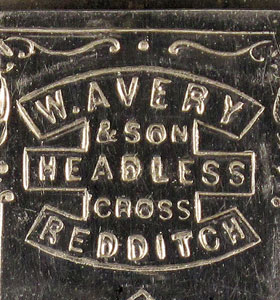

Silver Casket - Headless Cross

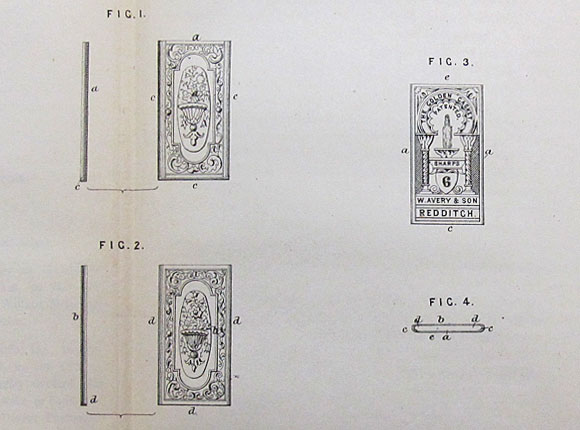

Needle Case (front)

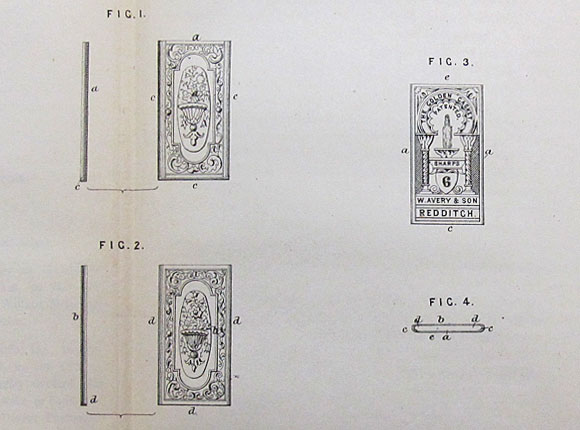

Patent 1868-58

Design Details

Needle Case Type: |

Flat-Names |

Patent/Registered to: |

William Avery of the firm William Avery & Son, Needle Manufacturer from Redditch |

Patent/Design Representation #: |

Mechanical Patent #: 58 |

Patent/Design Registration Date: |

January 7, 1868 |

Location of Patent/Design Registration: |

British Library - Business and Intellectual Property Centre - London

|

Reference #: |

1868-58 |

Dimensions: |

4.7 x 2.2 and 4.2 x 2.3 and 4.8 x 2.3 |

Material: |

Nickel-silver or nickel-plating |

Name Variations: |

W. Avery & Son - Redditch |

Other Variations: |

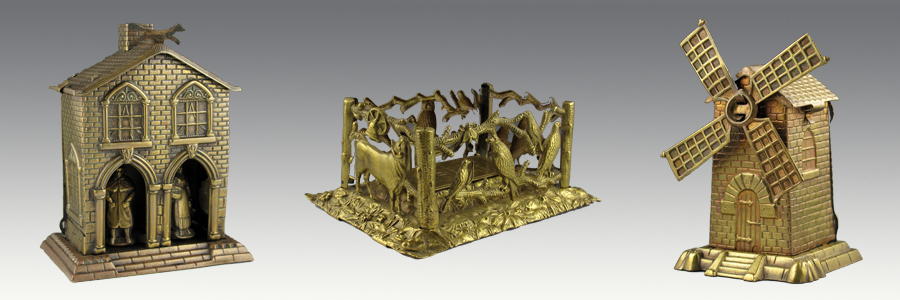

a) Silver Casket - Diamond

b) Silver Casket - Flowers

c) Silver Casket - Toronto |

Additional Photographs

Back and back signature detail

Back and front details

Silver

Silver is a grayish white shiny metal used to make mirrors, jewelry, silverware, coins and other ornamental objects. Because it is a

precious metal, items made with silver often contain a small percentage of another metal. For example, most sterling silver is an alloy of

92.5% silver with 7.5% copper. Items made of silver usually contain some type of hallmark identifying them as such. Similar hallmarks

are used to indicate whether an item is silver-plated. As a result, any item that appears to be made of silver but lacks the appropriate

hallmark is usually made of something else. During the 19th century many items were made of or plated with nickel-silver because its

appearance was similar to silver but it was much less expensive and didn’t tarnish like silver does. A detailed photograph of an Avery

needle case hallmarked as silver is shown below. Click on the photo to visit the webpage for this needle case.

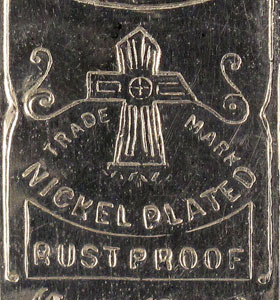

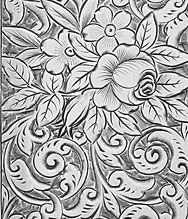

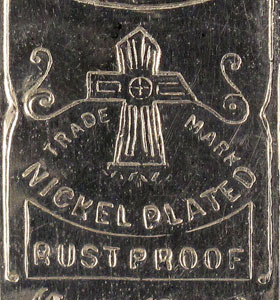

Nickel-Silver

Nickel-silver is an alloy of copper, zinc and nickel. The most common formula is 60% copper, 20% nickel and 20% zinc. Nickel-silver

was originally developed in China and the alloy was exported to Europe during the 17th century. German imitations began to appear around 1750

and in 1823 a competition was held in Germany to perfect the alloy which had the appearance of silver but was much less costly. The end result

was a product known as “German silver” or nickel-silver. Nine years later in 1832 a form of nickel-silver was also developed in Birmingham,

England where it became a popular metal used in manufacturing decorative items during the Victorian Period. When examining an item that

appears to be made of silver but lacks the appropriate hallmarks, it is often difficult to tell whether it is made of nickel-silver or plated with

nickel-silver. The photograph below is a detail of a needle case that appears to be made of nickel-silver. Click on the photo to visit

the webpage for this needle case.

Electroplating

Electroplating involves placing a thin layer of gold, silver or nickel onto an object made of another metal, such as brass, bronze or

copper. Avery style needle cases were most likely plated with nickel to give them the appearance of silver. Although an older plating

process had been around for years electroplating, which was invented in the early 1800s, proved less expensive because it required less metal and

could be done in a more efficient manner. A bath, consisting of water, sulfate of nickel and ammonium, was prepared in a container made of a

non-conductive material such as earthenware to which a plate of nickel was added. Prior to immersion, workmen attached the items to be plated

to a metal rod and then submerged them in the solution. They connected the nickel plate to the positive pole of a battery, and the metal rod,

on which the items were hung, to the negative pole. The electrical current passing through the solution caused the nickel from the sulfate

bath to condense on the object, while the nickel from the plate dissolved and became nickel sulfate. The length of time the item remained in

the bath determined the thickness of the plate. Because over 130 years have passed since Avery needle cases were made, ones that were

electroplated usually show evidence of wear and one can often see the brass showing through as in the detailed example below. Click on the

photo to visit the webpage for this needle case.