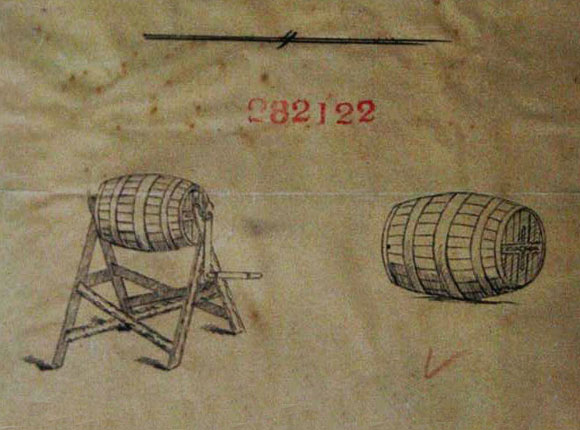

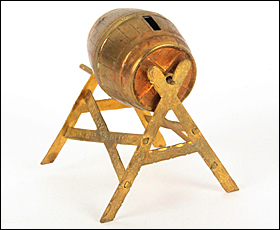

Butter Churn

Formerly known as the Barrel on Stand

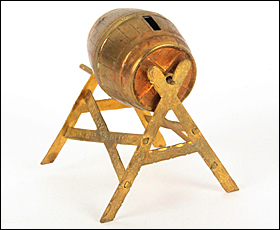

Needle Case Front View

A special thank you goes to Robert Bleasdale for sharing photographs of this item with us. Twice each year his company, Bleasdale Ltd. in Warwick, UK, has a sewing tool auction, once in the

summer and again in the winter, where many wonderful needle work tools are sold, several which were purchased by the author of this website. Be sure and check out their website

at Bleasdale Ltd.

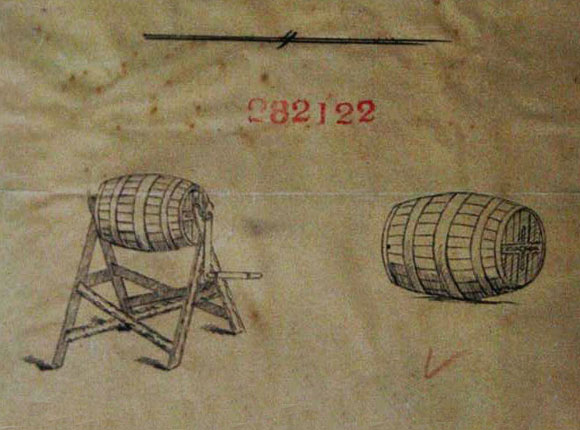

Design Representation

Design Details

Needle Case Type: |

Figural |

Patent/Registered to: |

Buncher & Haseler - Birmingham |

Patent/Design Representation #: |

Ornamental Class1: Metal: #282122 |

Patent/Design Registration Date: |

May 4, 1874 |

Location of Patent/Design Registration: |

The National Archives (TNA) - Kew, UK |

Reference #: |

TNA Representation - BT 43/36/282122

TNA Register - BT 44/3/282122 |

Dimensions: |

2 1/2 x 1 3/4 (these dimensions are in inches rather than centimeters) |

Material: |

Brass |

Name Variations: |

W. Avery & Son - Redditch |

Other Variations: |

None |

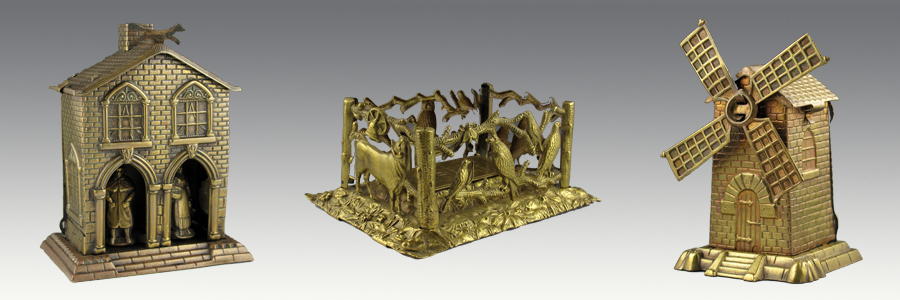

Additional Photographs

Left: back view. Right: side view.

Other side view

Facts

Butter is made by physically agitating milk cream to break down the membranes surrounding milk fat to allow the fat to clump together into

butter grains. With further agitation the butter grains join together to separate from the remaining liquid, butter milk, which is

drained off. The butter is kneaded to remove excess liquid and to finely disperse any liquid droplets so that the final texture appears

dry. The use of butter has been traced back for thousands of years. It takes 10.2 litres of milk to make one pound (454gms) of

butter. Butter has a yellow colour naturally from carotene that occurs in milk as a result of the cow’s diet.

History

It has been suggested that the first butter might have been made accidentally when milk was carried in an animal skin container hung on a

moving pack animal. Over time there have been several types of devices employed to make butter. One of the earliest and most

common is a container, often wooden, with a plunger which is agitated up and down. More sophisticated is a container with a hand operated

paddle(s) followed in the mid18th century by the barrel churn. William Ellis wrote in the Country Housewife’s Family Companion, 1750

“A barrel churn is so late an invention, that the uses of it are known but in few counties in England. Buckinghamshire and Bedfordshire

justly claim the first practice of this most serviceable dairy utensil, that every year comes more and more into fashion, for it being easily

and quickly clean’d (sic), as well as its being work’d (sic) with much facility and least waste of cream, and expeditiously producing the

sweetest butter.”

Miscellaneous

The Household Cyclopedia of 1881 instructs:

“Let the cream be at the temperature of 55° to 60°, by a Fahrenheit thermometer; this is very important. If the weather be cold put

boiling water into the churn for half an hour before you want to use it; when that is poured off strain in the cream through a butter

cloth. When the butter is coming, which is easily ascertained by the sound, take off the lid, and with a small, flat board scrape down

the sides of the churn, and do the same to the lid: this prevents waste. When the butter is come the butter-milk is to be poured off and

spring water put into the churn, and turned for two or three minutes; this is to be then poured away and fresh added, and again the handle

turned for a minute or two. Should there be the least milkiness when this is poured from the churn, more must be put in.”

Note: Right side panel text and photos provided by Lynda Herrod.